Humidification & humidity control for Army and Defense

Proper Humidity is Essential to the Readiness and Reliability of Defense Systems and Equipment. Insufficient humidity levels in your storage and operations facilities can cause problematic ESD occurrences, component failures, ammunition malfunctions, reduced equipment performance and hinder the uptime of vehicles and equipment. Ensuring proper humidification in your storage and operations facilities ensures maximum reliability, leading to increased training and operational readiness.

Maintain High Reliability Standards and Uptime Requirements

Proper humidification is essential to maintaining high reliability standards and uptime requirements with avionics and electrical components. Insufficient humidity levels can lead to electrical component failure and malfunction, which can impede operations and lead to unsafe situations caused by malfunctioning equipment.

Ensuring your facilities are maintained at a relative humidity level of 40-60% RH results in maximum equipment performance and readiness. Proper humidity contributes to reduced maintenance and need for spares, maximized available training time, increased training and readiness metrics and supports the highest number of combat-ready units at any given time.

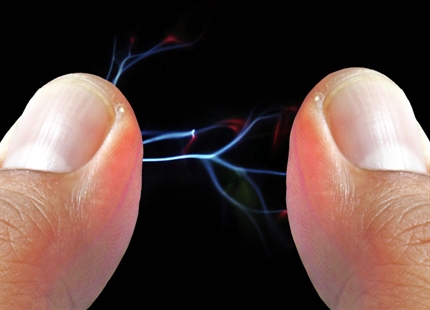

Reduce ESD and Component Failures

Maintaining optimal humidity levels in your storage facilities and training centers reduces the chances of electrostatic discharge (ESD). ESD can cause damage to electrical components, failure of electronic components and operational systems, and put your personnel at risk due to the potential for electrical shock or combustion.

Keeping indoor air environments maintained at a relative humidity level of 40-60% RH prevents these expensive and unsafe electronic component failures. This leads to a wide range of benefits, including increased uptime of avionics and electronics systems, maximized available training time, improved personnel training levels and readiness as well as additional missions completed.

Ensure Maximum Operational Readiness and Durability with Reliable Coatings

To deliver maximum performance readiness and durability, equipment requires quality coatings. Painting military vehicles and equipment requires a low static environment for proper application.

Maintaining an indoor environment between 40-60% RH is ideal for electrostatic paint and powder coating in order to create an even, durable coat. Coating in these ideal conditions delivers improved first pass coating results, reduced paint waste and rework, higher equipment readiness rates, increased up time, as well as higher operational readiness and mission accomplishments.

Ensure Optimal Ammunition Performance

Preventing chemical degradation in your ammunition storage facilities and operations is integral to personnel safety and mission success. Maintaining optimal relative humidity levels is integral to the prevention of chemical degradation in military ammunition. Ammunition stored in a consistent humidity environment provides increased combat readiness and usage rates.

Ammunition, gun powder, explosives and any combustible materials being handled have a high risk of danger if there is any spark of static discharge is present. Proper humidification levels significantly reduce chances of static discharge. This leads to reduced explosion hazards, safer working environments, increased material readiness and usage rates, maximized training time, higher operational readiness posture and mission accomplishment rates. Maintaining proper humidity levels of 50-60% RH in ammunition storage areas provides maximized safe shelf life, improved ammunition utilization rates, higher weapons systems qualification rates, and increased mission readiness posture across all departments.

Benefits of humidification for the army and defense industry include:

- Mantain safe working environment

- Increase training capacity and readiness

- Ensure equipment and system reliability

- Prevent costly and unsafe component failures

Other industries where Condair delivers vital humidity control include...

Packaging humidification

Reducing static and maintaining the properties of paper, card and adhesives.

Read moreHumidification for dust suppression

Humidifiers suppress dust, reduce dust emissions, dust deposits and neutralise odours.

Read moreWoodworking humidification

Individuals in the woodworking field such as furniture, cabinetry, and flooring manufacturers often encounter manufacturing issued caused by dry air.

Read moreData centre humidification

Provides high capacity, low cost evaporative cooling and combats ESD.

Read moreEliminating static with humidification

45-55%RH eliminates the build-up of static electricity in manufacturing environments.

Read moreTextile manufacturing humidification

For improved yield & quality.

Read morePrinting humidification

Prevents dimensional change and improves production processes.

Read morePharmaceutical manufacturing humidification

Increases efficiency & yields.

Read morePaper & pulp production humidification

Prevents dimensional changes.

Read moreMedical device manufacturing humidification

Prevents chemical imbalances.

Read more