NEW with additional features!

Condair RS - the 7th generation of a successful technology

Resistive steam humidifier

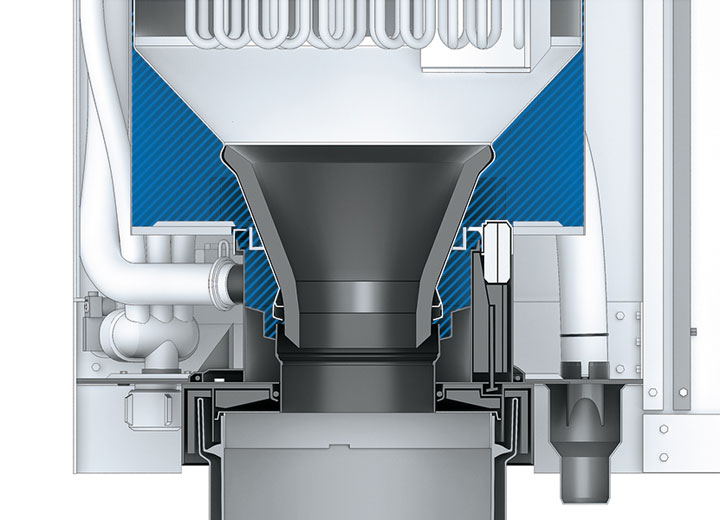

This electric steam humidifier delivers accurate humidity control without the expense of plastic disposable boiling cylinders and simplifies maintenance with its patented scale management system.

Scale that forms on the heating elements breaks off under normal operation and falls into the externally located scale collector tank. Scale removal is a simple process of draining the scale collector tank with the push of a button, allowing the unit to cool then disconnecting the tank and emptying it.

The Condair RS can operate with mains water to provide ±3%RH control or on reverse osmosis (RO) water to offer ±1%RH control. When operating on RO water, scale build-up is virtually eliminated, significantly reducing the unit's required maintenance.

By locating the water inlet and drain between the twin walls of the outer cylinder wall and an inner cylinder liner, the temperature is kept at a level that inhibits scale formation in this area. This "cold water pool" prevents blockages of the inlet and drain by scale to further enable extended periods between servicing.

An advanced touch screen controller provides intuitive control over operation and very detailed reporting, including downloading performance, fault and service history into Excel for advanced diagnostics. BMS connectivity is standard with BACnet and Modbus protocols, with optional LonWorks connectivity.

Condair EL

Electrode boiler steam humidifier

The Condair EL electrode boiler steam humidifier offers hygienic steam humidification with the convenience of servicing through quick and simple cylinder replacement.

Advanced water conductivity management and staged electrode use enables Condair EL steam cylinders to last significantly longer than other electrode humidifiers', reducing service requirements and operating costs.

The Condair EL incorporates the latest touch screen technology for intuitive user operation and advanced reporting. A USB port allows performance and maintenance data to be downloaded and analysed in Excel.

Features & benefits

- Convenient and fast servicing through cylinder replacement

- Exceptionally long cylinder lifetime

- Touch screen control panel

- BMS connectivity as standard

- USB port for diagnostic reporting in Excel

- Stage electrode use for optimum performance throughout cylinder life

Condair Outdoor unit

New Condair outdoor steam humidifier

Condair has extended its range of electric steam humidifiers to include new IP55 rated models suitable for outdoor installation. The robust enclosures on the Condair RS resistive steam and Condair EL electrode boiler steam humidifiers enable the units to be located on rooftops and exposed to the elements.

Rather than simply installing the standard humidifiers inside a protective housing on a rooftop, the new outdoor humidifiers from Condair have purpose-built IP55-rated casings. This means they take up much less room on a rooftop and are easier to install. Condair’s new outdoor humidifiers are the most compact in the industry with the smallest footprint and incorporate lifting handles to make on-site transportation easier.

The enclosures incorporate a thermostat-controlled heater and fan unit to maintain the internal temperature at an optimum level with outside ambient conditions ranging from -20° to 40°C. An anti-freeze valve will ensure the humidifier completely drains should the unit experience temperatures of less than 6°C during periods of in-operation.

The new Condair outdoor humidifiers can be wall-mounted, allowing them to be attached to an AHU, or free-standing. Lockable doors are removable for easy access and optional internal lighting improves visibility for servicing and maintenance.

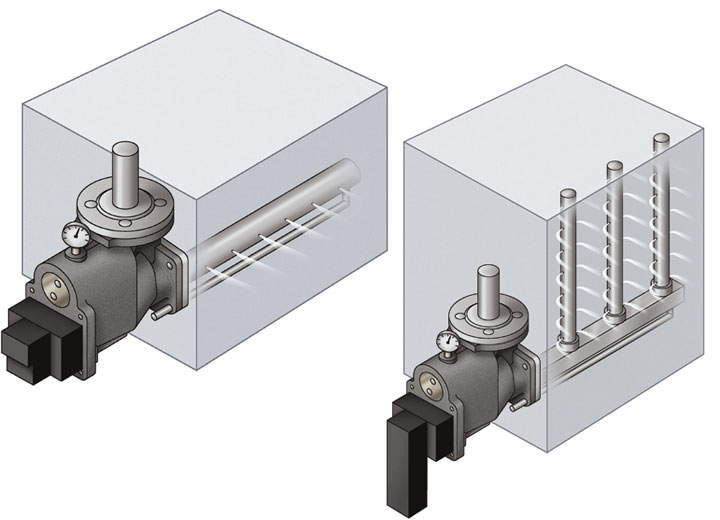

Condair GS

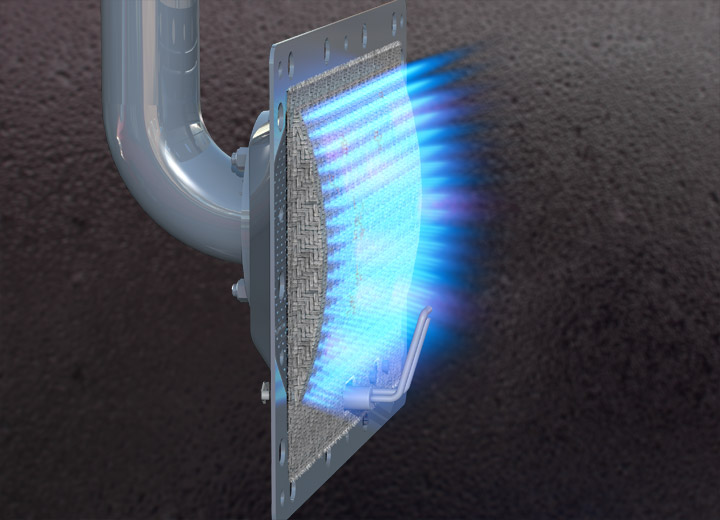

Gas-fired steam humidifier

The Condair GS offers high capacity steam humidification with low operating costs. The economy of using gas makes this humidifier around 60% cheaper to power than an equivalent electric steam humidifier. This can provide a fast payback when replacing electric steam, especially on high capacity systems.

The Condair GS is available in six different output variants, allowing continuous adjustment from 10 kg/h to a maximum of 240 kg/h. The microprocessor-controlled device interface can be operated with all commonly-used control signals.

Features & benefits

NEW High energy efficiency with optional condensing heat exchanger

- Large steam outputs with the economy of gas heating

- Can used mains, RO or softened water

- Large flat surfaces on heat exchanger for easy scale removal

- Water conductivity management for reduced scale build-up and closer humidity control

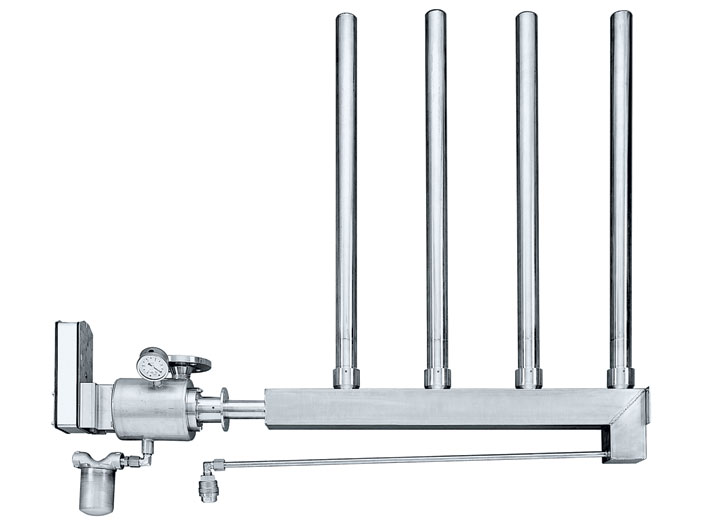

Condair ESCO

Live steam humidifier

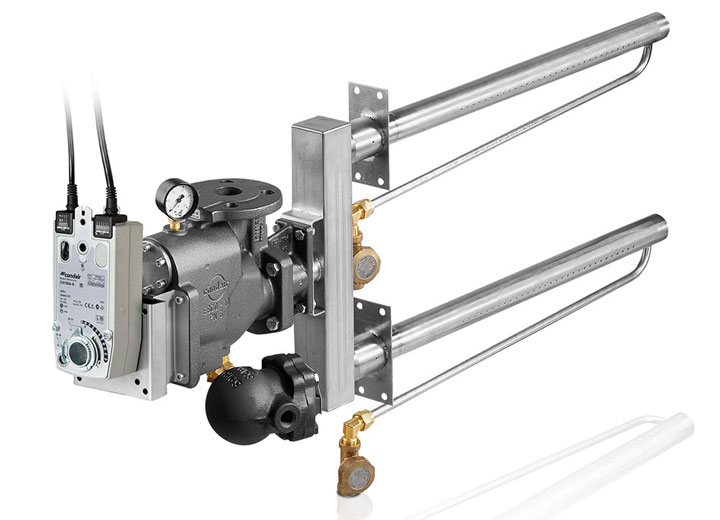

The Condair ESCO uses steam from a building’s existing steam network to provide humidification to an air handling unit (AHU) or duct. It conditions the steam to remove condensation and ensures that only dry steam is delivered for humidity control.

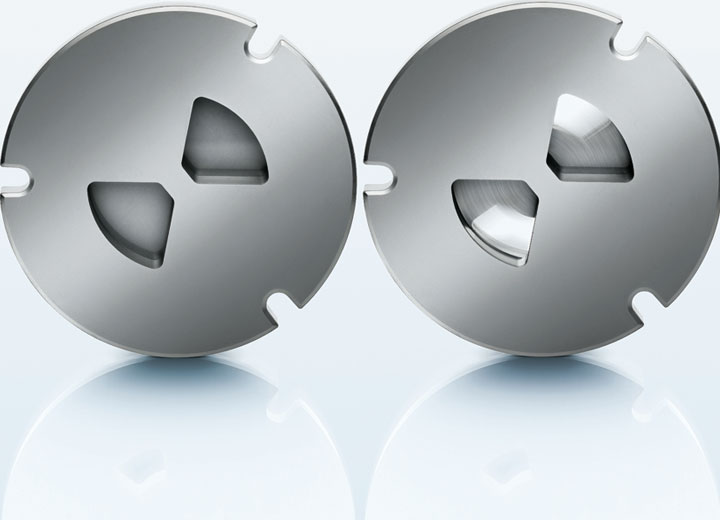

It can operate at up to 4bar and provide up to 1,000kg/hr of humidification to an AHU. It incorporates a ceramic rotary disc valve that offers 0-100% modulation, very close control and prevents the possibility of steam leakage when closed.

The Condair ESCO’s patented steam lance has tiny inner nozzles that draw steam only from the centre of the steam lance, where it is at its hottest and driest. This ensures that any condensation that occurs around the cooler outer edges is not introduced to the duct.

Features & benefits

- Uses a building's existing steam supply

- High capacity up to 1,000kg/h

- Operates at up to 4bar

- Ceramic rotary valve 0-100% modulation

- Patented steam lance without the need for pre-heating and fast response for humidity

Condair Optisorp

Short evaporation steam distribution manifold

The OptiSorp steam distribution manifold shortens the evaporation distance of steam released inside a duct or air handling unit (AHU). This prevents steam from coming into contact with components or corners within the AHU and ensures reliable and hygienic steam humidification.

Tiny patented inner nozzles on the manifold draw steam from the centre of the steam pipe where it is at its hottest and driest. This guarantees that steam is introduced to the AHU without “spitting” that can occur when condensation forms around the cooler outer surface of the pipe.

Features & benefits

- Up to four times shorter evaporation than standard steam pipes

- Patented inner nozzles guarantee dry steam delivery

- Uniform steam distribution across the duct and accurate humidity control

- Stainless steel construction for long operational life